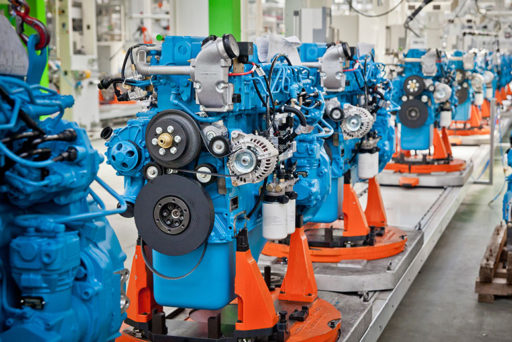

Иторум — одна из ведущих компаний на рынке технической документации с более чем 10-летним опытом. Основная наша цель: постоянное улучшение качества работ за счет активного внедрения инновационных технологий. Благодаря накопленному межотраслевому опыту и пониманию потребностей заказчиков, нам удается уже после первой встречи предложить эффективное решение проблемы. Среди наших партнеров — компании-лидеры в своих отраслях.

Technical Documentation Editor 3D (TDE 3D) отечественное программное обеспечение предназначенное для автоматизации процессов создания высококачественной 2D и 3D графики для ИЭТР. Основные цели разработки TDE 3D: замена систем зарубежных производителей для разработки графической части (Corel Draw Technical Suite, XVL 3D Studio, PTC Arbortext IsoDraw, Cortona3D и т.д.); использование интегрированных решений для разработки ИЭТР. TDE 3D […]

8 июня 2023 г. компания «Иторум» и НИЦ «Прикладная логистика» провели восьмой семинар по теме «Интегрированная логистическая поддержке наукоемкой продукции». В рамках семинара были доклады и обсуждения по различным направлениям интегрированной логистической поддержки (ИЛП), включая: информационную поддержку процессов эксплуатации и ремонта; программные продукты и нормативы для решения различных задач ИЛП; результаты проектов в области ИЛП, […]

ИЭТР – это интерактивное электронное техническое руководство, включающее эксплуатационную, ремонтную или справочную документацию, выполненную в интерактивной форме. Заказать создание ИЭТР можно в компании Иторум. Услуга будет предоставлена в сжатые сроки и с максимальным качеством. Разработкой занимаются специалисты с большим опытом.

Эффективное решение задач интегрированной логистической поддержки изделия обеспечивается за счет использования специализированного комплекса программных продуктов. Схема решения Комплекса ПО для решения задач ИЛП включает: систему управления данными об изделии на базе PDM|PLM; модуль для решения задач анализа логистической поддержки на основе Logistic Support Analysis Suite (LSS) или Integrated Logistic Support Suite (ILS); модуль разработки и поставки пользователям эксплуатационной и ремонтной документации, включающий […]